Cathodic protection systems prevent corrosion of pipelines, bottoms of above ground storage tanks, plant piping and many other buried or submerged steel metal structures.

The main concern of the operators of these assets is to increase their service life. Since corrosion is the main cause of premature failure, regular installation and testing of cathodic protection systems is a popular solution.

A wide variety of civil and industrial applications use cathodic protection systems for many years of corrosion protection. Installation is usually carried out during the main construction, major extension or upgrade.

This article covers the basics, but also goes into more detail in our FAQ. Additionally, we provide a forum to ask your questions.

Galvanic cathodic protection

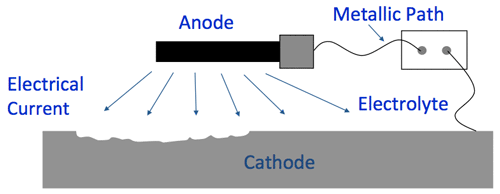

A galvanic system uses anodes connected to a protected structure in a circuit. Additionally, galvanic anodes use the natural voltage differential or potential between the anode (more negative) and the structure (less negative) to draw current from the anode and structure.

Galvanic anodes (also called sacrificial anodes) can protect underground, marine, domestic, and industrial steel structures from corrosion when properly applied and with certain limitations. Galvanic CP systems do not require an external power source to operate. In addition, these anodes can be both long lasting and easy to operate.

Galvanic anodes are available with a variety of features, including:

- Bare metal anodes such as magnesium, zinc, aluminum and other alloys

- Back packing for underground use

- External steel straps for installation on structures

- Several types of ribbons

- Bars and special shapes